RV Education 101 - How To's

RV Care Tips

Hi, my name’s David Robinson. I’m the marketing manager here at Roadmaster, and we’re about to take a factory tour. Before we get started, I just wanted to mention a couple of things that kind of set Roadmaster apart. The biggest thing is that we are a true manufacturer. We literally take raw steel and turn it into finished product. There’s a lot of companies out there that call themselves manufacturers, but essentially they’re assembly shops. They bring in parts from overseas, they put them in a box, bolt it together, and they call that manufacturing. We literally make the parts that make the assemblies that turn into finished goods.

The other thing is that Roadmaster is really big on testing. As you go through, you’ll see a lot of testing that we do. It’s stuff that other people might do 1 in 100 or 1 in 50. We do one for one. Every part that comes out of here gets tested.

Let me just show you a little bit of our raw material. This is how it comes in. It usually comes in in 12-, 20-, or 40-foot lengths of steel or aluminum or brass. From that, we put it through our turning centers, our saws to cut it down to size, and we start turning it into pieces. Come on, and let’s go take a look.

So, one of the first things that we do is we take our long lengths of steel, and we cut it down to size. So typically, we will take several layers of steel, weld them together so that they don’t shift, and we’ll bundle cut them. We’ll program the machine to tell it how long of a piece that needs to be cut. And then it will swathe through, it’ll cut through all layers of the steel. It will automatically raise itself back up, it’ll grab ahold of the steel, and it’ll pull it through to the correct length, and then start all over again. All we have to do is have somebody on the end of the line pulling the cut parts off. So, the parts that we’re cutting right now are actually the collars that will go around a two-inch receiver tube. We make a lot of drop hitches and hitch accessories, so this collar will literally be welded around a normal receiver.

Here at Roadmaster, not only do we manufacture steel products, but we also design and engineer them. Currently, we’re back here in our R&D department. This is where we bring in cars and motorhomes, and we’ll literally create the brackets or the sway bars, steering stabilizers, whatever bracketry or steel is necessary to fit a particular vehicle. So, in this particular case, we’ve got the bumper facia off the front of the car, and we will be designing the brackets and the framework that will be required to have a proper, secure, and safe attachment for a tow bar.

Now, after it’s been designed, they’ll take it into our FEA office– that’s a finite elemental analysis– and what we’re doing there is we’re drawing it up, and we’re actually computer testing it to make sure that there’s no hot spots or any areas that might need reinforcement or gussets. If so, we will add those parts. And once we have a product that we feel comfortable with, then we’ll go ahead and design a finished good, check for fit, check to make sure that everything goes on and off properly. In a nutshell, a very simplified version of how we design brackets for our tows bars.

In the case of this particular car, the reason it’s in here is we’re making a new version of our brackets. We’ve actually had a bracket to fit this year of vehicle for a long time, but in the last couple of years, we’ve designed a new style of bracket that customers really appreciate. It’s very hidden, it has safety cable attachments on it. It has mounting brackets that you can hook up your electrical connector to, a place for your breakaway switch if you have a braking system. So, what we’ve done is brought this back in so that we can redesign a whole new bracket in the improved version.

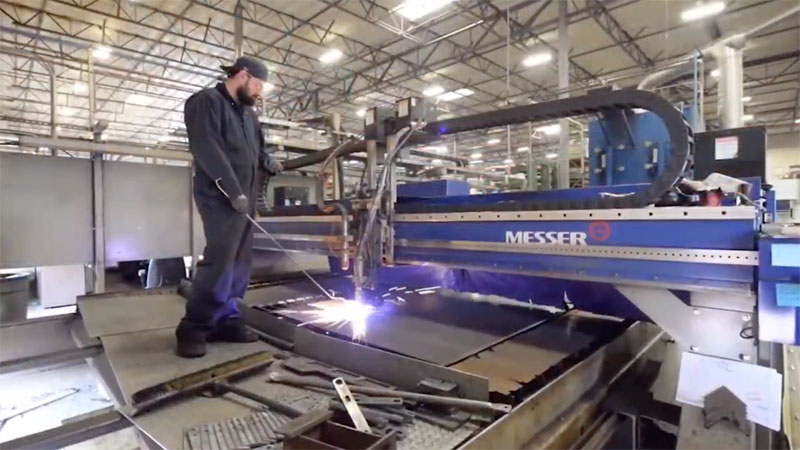

So, this is a pile of scrap metal. This is what’s left over after we either plasma cut or laser cut steel parts out of it. You’ll notice that there’s very little waste. And a lot of that is due to computer programming. Our laser tables are smart enough to find out where the holes are going to be, where the wasted patterns are going to be found. And it will recommend small parts that we could use to fill in those holes. Also, the computer will actually tell you the most efficient pattern to cut. So, it will lay out, you just tell it how many parts you want to build and of what part number. It’ll computer generate it onto the sheet, and then it will go back and fill in to maximize the space, as well as to recommend possible smaller parts that can consume the remaining material.

David: So, this is an example of a jig. A jig is essentially a pattern that will allow us to replicate a piece of steel on an assembly over and over again. Essentially, it’s like a jigsaw puzzle. And it will hold all of the individual pieces and parts of steel in place so that we can tack weld them. What I want to point out here is that every time a car changes, we have to make a new jig. So, Roadmaster has over 1,200 unique jigs just for brackets. This is just to adapt tow bars to cars. And those 1,200 jigs will allow us to fit approximately 2,000 different years, makes, and models of vehicles. This is an example of one of our newer styles of brackets. And with this bracket, we have a rotating arm. And that assembly can be twisted and removed easily so that when you’re not towing, there’s nothing visible on the front of the car. Also, these are the mounting posts, where the electrical socket will attach. This is the bracket where your breakaway switch will mount. And then also out here is where your safety cables are going to attach. So, it’s a very well thought out design, so everything’s clean and mostly invisible when you’re not towing.

A lot of people don’t realize that Roadmaster makes a lot of things unrelated to the RV industry. For example, what you’re looking at right now is a screen that separates a criminal from a police officer. This is actually the shield that goes between the front seat and the back seat of a police car.

This is our bead blaster. So essentially, you’ll see this tree. We’ll hang the raw steel parts on it. It replaces a sand blaster. There’s four motors on the side. It’s kicking a steel shot, it’s like a huge pinball machine in there. And what it’s doing is knocking all the mill scale off. And the reason we do that is to get a good powder coat, to get a good finish on it.

This is a stamping die. And these are actually like the giant cookie cutters that will chomp pieces of steel out one after the other after the other. This whole area of our factory, everything in here is something most factories don’t have. Normally when you want

a stamping die, you’ll create a drawing, you’ll send it to an outside company, and they will create tool steel, create these stamping dies. Might take 6 to 8 weeks, maybe 12. Might be $10,000, $20,000, $30,000 later, then you can start stamping out parts.

Roadmaster actually has the machinery to cut the die steel, which is so hard you can’t file on it. So, we make our own stamping dies. And what that allows us to do is make changes to our parts faster. We don’t have to wait the three or four months to have them. And it reduces the cost of creating each stamping die by significant margin.

Roadmaster has 21 welding booths. We also do heliarc welding, so we weld aluminum as well. But the ventilation does a great job of drawing up all of the fumes, so we have a very clean, nice work environment here. We’ve got some of the best welders in the industry, and that enables us to have some of the strongest products made. This is an example of a CNC turning center. Essentially, we chuck up long sticks of steel, and we turn them down into finished parts. For example, the part you’re seeing here will end up being the stinger bolt

Roadmaster has 21 welding booths. We also do heliarc welding, so we weld aluminum as well. But the ventilation does a great job of drawing up all of the fumes, so we have a very clean, nice work environment here. We’ve got some of the best welders in the industry, and that enables us to have some of the strongest products made. This is an example of a CNC turning center. Essentially, we chuck up long sticks of steel, and we turn them down into finished parts. For example, the part you’re seeing here will end up being the stinger bolt

that will go inside of a tow bar. The CNC turning centers, we have over a dozen of them in the factory. Each of them is a fairly major investment, but it’s another example of how far Roadmaster has gone to make sure that we can control the quality and make sure that we can produce the parts that we need in the timeframe that we need them.

Besides tow bars, Roadmaster makes a lot of suspension products. So, we make rear sway bars, front sway bars. We make steering stabilizers, we make front and rear track bars. So, Roadmaster makes all of the different products that are necessary and useful to help make the coach go down the road in a safer and more stable fashion. There’s a big rig myth in the industry that, well, it’s a big rig, it’s got to handle like a big truck. And it really doesn’t. We make the products that will make it handle much more like your car does. So, whether we’re manufacturing it for the OEMs or for the aftermarket or for some private label customers, these are some examples

of different sway bars that we make.

You’ll notice some very involved bends. We have computerized bending equipment so that we get precisely the same bend each time. Just another example of things we do outside of the traditional tow bar channel. So, we’ve seen a number of parts being cut. We’ve seen some things being lathed. We’ve seen some parts being turned. So, whatever the part is, at some point it’ll come to this area. This is our assembly area. This is where everything gets bolted or put together, instructions get added, parts get boxed, protection gets put in the box for shipping, and it gets sealed up and then sent over to our warehouse for shipping.

You’ll notice some very involved bends. We have computerized bending equipment so that we get precisely the same bend each time. Just another example of things we do outside of the traditional tow bar channel. So, we’ve seen a number of parts being cut. We’ve seen some things being lathed. We’ve seen some parts being turned. So, whatever the part is, at some point it’ll come to this area. This is our assembly area. This is where everything gets bolted or put together, instructions get added, parts get boxed, protection gets put in the box for shipping, and it gets sealed up and then sent over to our warehouse for shipping.

In this part of the plant, this is where we manufacture our braking systems. So, we have what we call invisibrake, an invisible braking system. We have breaking the box systems like the even brake. And we have our pneumatic air braking systems that work very well with air brake coaches called the Brakemaster. In addition to the braking systems, we also manufacture our diodes, we manufacture our tail light wiring converters, our power cords, some of our safety cables.

All the packaging occurs up here, and that’s kind of unique. A lot of companies send parts out to be packaged elsewhere. We do that, we do blister packing here, clamshell packaging. The other thing that we do is sewing. We have our own sewing department. You know, those are all things that we could have done, you know, overseas for a lot less money, but we like to keep the work here, we like to keep the American workers employed. And it also allows us to control both the quality and the quantity. And the owner of our company says quite often, you can’t tack quality on at the end. You have to build it in.

All the packaging occurs up here, and that’s kind of unique. A lot of companies send parts out to be packaged elsewhere. We do that, we do blister packing here, clamshell packaging. The other thing that we do is sewing. We have our own sewing department. You know, those are all things that we could have done, you know, overseas for a lot less money, but we like to keep the work here, we like to keep the American workers employed. And it also allows us to control both the quality and the quantity. And the owner of our company says quite often, you can’t tack quality on at the end. You have to build it in.

And so, we like to take control of the entire process from the very beginning, where we actually take raw steel and raw parts, all the way to the end, where we actually package it, paint it, package it, and put it into retail boxes.

Well, that about wraps it up for our factory tour. We want to thank you for your time. If you ever need anything from Roadmaster, you can reach us at 800-669-9690, or roadmasterinc.com.