rv Restoration

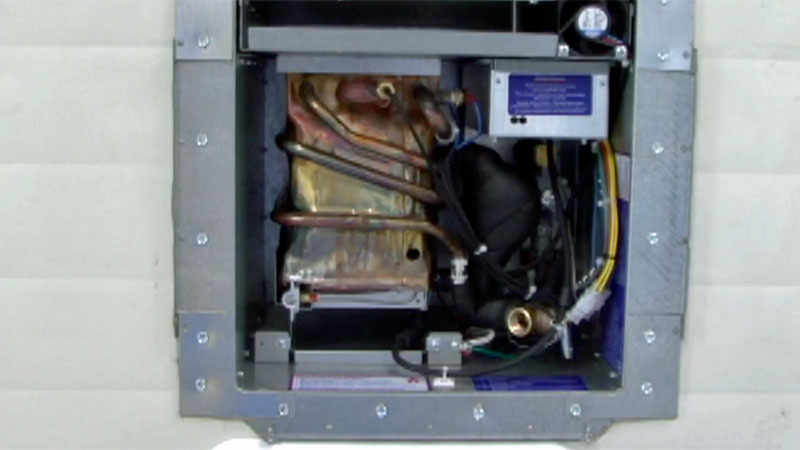

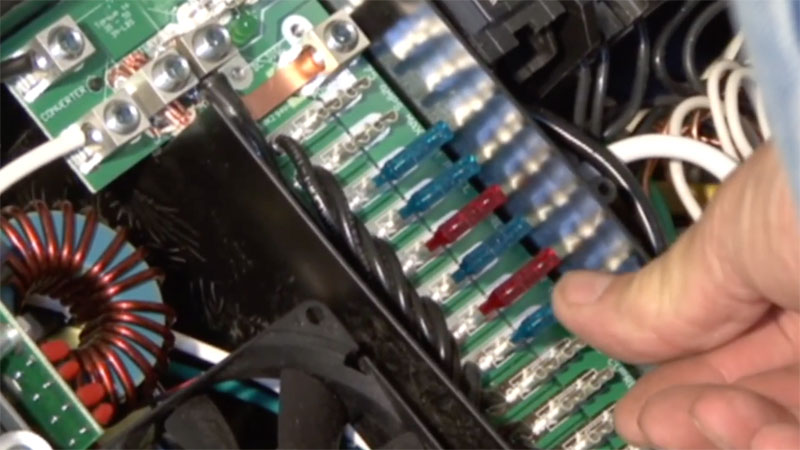

Welcome back to our ’67 Yellowstone trailer restoration project. We have a lot to do today. First, we’re gonna finish installing the bathroom, then we’ll finish connecting the 120-volt and 12-volt wiring to the new power distribution center.

After that’s done, we’ll tackle installing a new rubber roof on the trailer and get it prepped to install some appliances. There’s no time to waste, so let’s get started.